How we do

Each of our products has a soul because it has been designed, designed and manufactured with passion, dedication and professionalism, using the best possible technologies and where necessary relying on industry leaders of high value.

Suppliers

Quality

Fleet

Information Technology

certification

Ask for advice:

035 451 7251

SUPPLIERS

Ma-el has always developed partnerships with leading suppliers that guarantee a high standard of quality.

Ma-el personally selects suppliers for both raw material and for heat and galvanic treatments.

Ma-el suppliers are constantly monitored to maintain the high standard of quality that Ma-el customers need to have, but that Ma-el itself has set itself to achieve.

QUALITY

Quality is guaranteed by the meticulous control our products are subjected to towards the use of the latest technologies

2 CMM Wenzel twin machines to ensure the availability of NON stop control

CMM Smartscope OGP 203x zoom optical measuring machine

profile projectors

Durometer Test Hv1 and Hv30

Cleaning test (gravimetry and particle size)

roughness tester

Controllo del rivestimento

FMEA analysis

Process and product SPC

IMDS alert

ERP fully integrated with 100% traceability from raw material to finished products.

FLEET OF MACHINERY AND EQUIPMENT

Our machine fleet consists solely of European or Japanese manufactured equipment to ensure a high degree of reliability. This countercurrent choice is accompanied by an average age of the machines kept below 8 years to a maintenance program perfectly integrated with the production processes to ensure the highest standards of process reliability.

4 CAD stations with fully integrated 2D and 3D design software

3 Cam stations for EDM and CNC milling machine and lathe

Only top market German and Japanese CNC machines

Wire EDM machine with Erowa automation (available 8000h per year)

4 CNC milling machining centers up to 60 tools each up to 30,000 revolutions per minute

Multi function lathes

CNC grinding machines

Ability to work carbide

6 Transfer presses up to 300 TON

6 Mechanical presses up to 250 TON

3 Servo pumps up to 300 TON

information technology

The use of the most current technologies and the latest information systems testifies to our constant propensity for innovation, ensuring maximum security and confidentiality of customer data, encouraging the traceability and availability of all information and adaptability to the demands for change in the course of work.

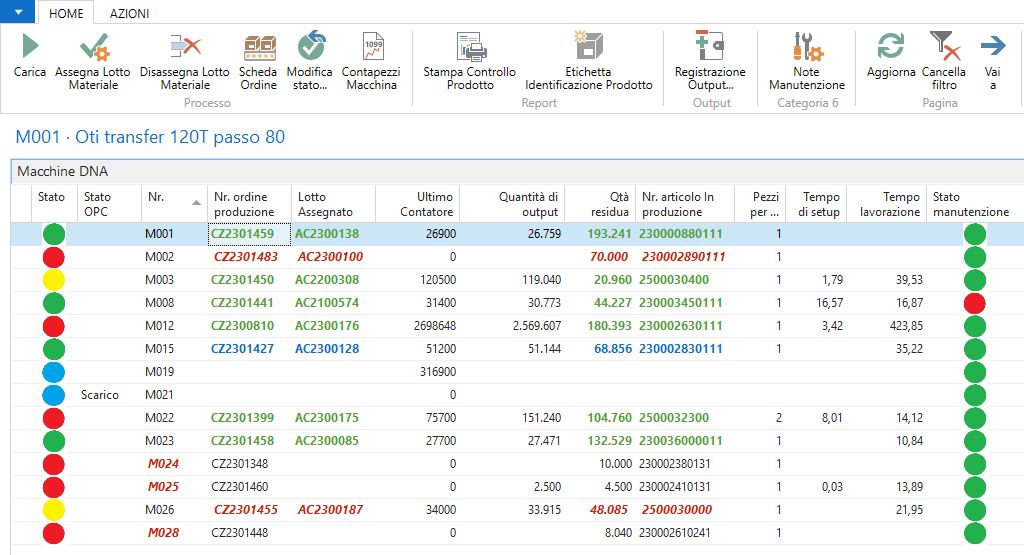

integrated production system

4.0 technology

100% traceability with automatic load recording

100% automated control systems

CERTIFICATE

With the obtaining of the most restrictive certifications of the industrial sector we have adhered to the philosophy that makes continuous improvement the foundation of our work. For this reason, we obtained the ISO 9001 certification already in 2001 and then obtained the ISO 16949 certifications subsequently modified in IATF 16949:2016 and ISO 14001 during 2011.